Researchers at the Delft University of Technology have developed new cerium-doped indium oxides for applications in heterojunction solar cells. A transparent conductive oxide built with the new compound has enabled a considerable increase in power conversion efficiency.

Scientists at Delft University of Technology (TU Delft) in the Netherlands have fabricated a front-back contact silicon heterojunction (FBC-SHJ) solar cell with a transparent conductive oxide (TCO) based on cerium-doped indium oxide (ICO) with the aim of increasing the device's opto-electrical performance.

“To increase power conversion efficiency further, one can follow the route of high-mobility TCO layers,” the research's lead author, Engin Özkol, told pv magazine. “We decided to explore cerium-doped indium oxide films for this purpose. It is known that Longi already uses hydrogenated indium oxides (ICO) layers grown via reactive plasma deposition (RPD) in its world-record solar cells. In this study, we employed budget-friendly room temperature radio frequency (RF) sputtering, which is available for most of the laboratories’ infrastructure, but somehow scarce in the literature.”

The researchers explained that ICO layers are particularly attractive for solar cell manufacturing due to their opto-electrical properties and room temperature deposition over indium tin oxide (ITO) counterparts. They used 35-nm-thick ICO films sputtered onto Corning Eagle XG glass substrates at room temperature.

“As the first step, we tuned process parameters to optimize ICO layers in terms of mobility, carrier concentration, resistivity and transmittance,” said Özkol. “We achieved a Hall mobility of 44.22 cm²/Vs, which is 56% higher than our baseline ITO, and resistivity as low as 8.56×10⁻⁴ Ω·cm. The second step was, of course, applying this layer on the solar cells.”

The research team built 2 × 2 cm2 sized cells onto fully passivated 4-inch round wafers.

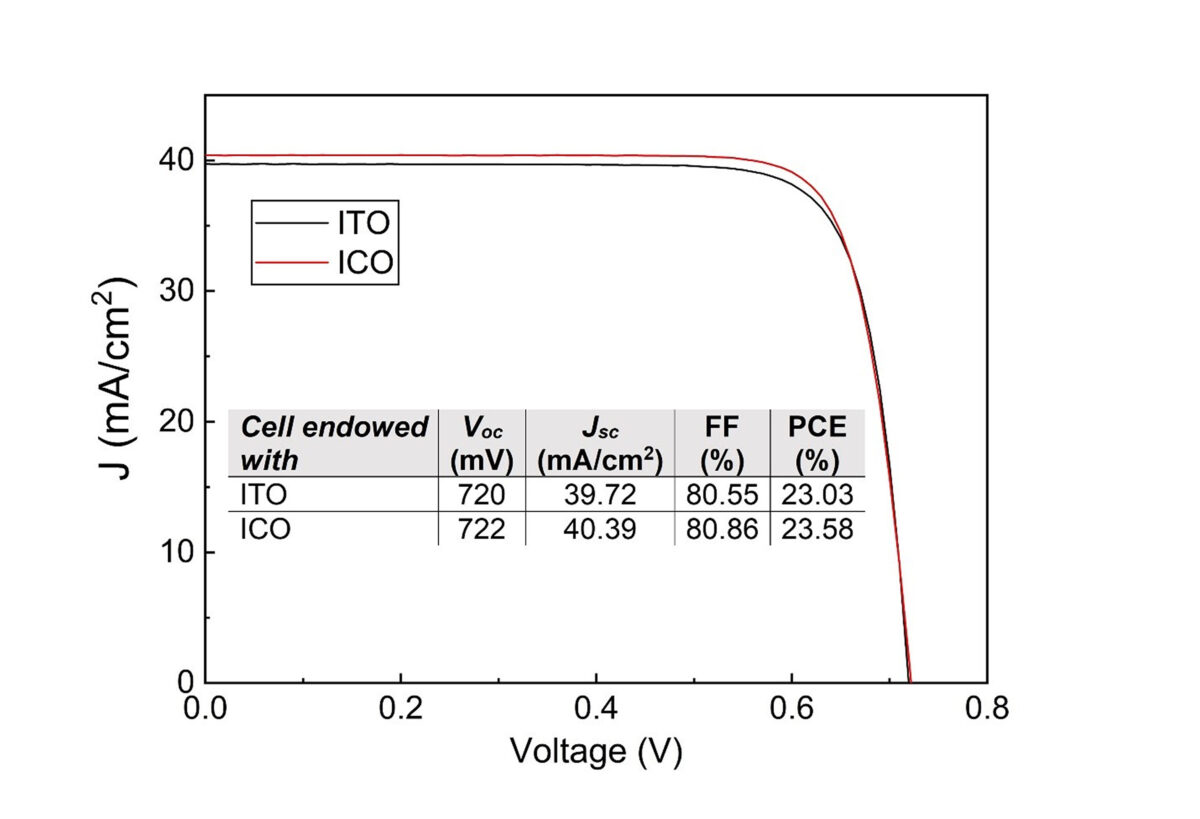

Tested under standard illumination conditions, the device achieved a power conversion efficiency of 23.58%, an open-circuit voltage of 722 mV, a short-circuit current of 40.39 mA/cm2, and a fill factor of 80.86%. A reference solar cell built with an ITO TCO reached an efficiency of 23.03%, an open-circuit voltage of 720 mV, a short-circuit current of 39.72 mA/cm2, and a fill factor of 80.55%.

“The opto-electrical enhancement of our ICO films with respect to the ITO reference layer was reflected at the device level, particularly for the short-circuit current, with an improvement of 0.67 mA/cm2 for ICO layers,” Özkol said. “To conclude, we demonstrated not only ICO’s potential as a powerful ITO alternative but also opened new doors for cost-effective, scalable, and low-temperature TCO fabrication for advanced PV technologies.”

The new cell concept was presented in the study “Optimization and integration of room temperature RF sputtered ICO as TCO layers in high-performance SHJ solar cells,” published in Solar Energy Materials and Solar Cells.

In April, other TU Delft researchers presented a rear junction silicon heterojunction solar cell with a localized front carrier-selective passivating contact that covers only the area contacted by the metal grid.